Wildfire Energy

Based: Brisbane, QLD

Industry: Energy

Winner of Sustainability Innovation Award presented by Wrays

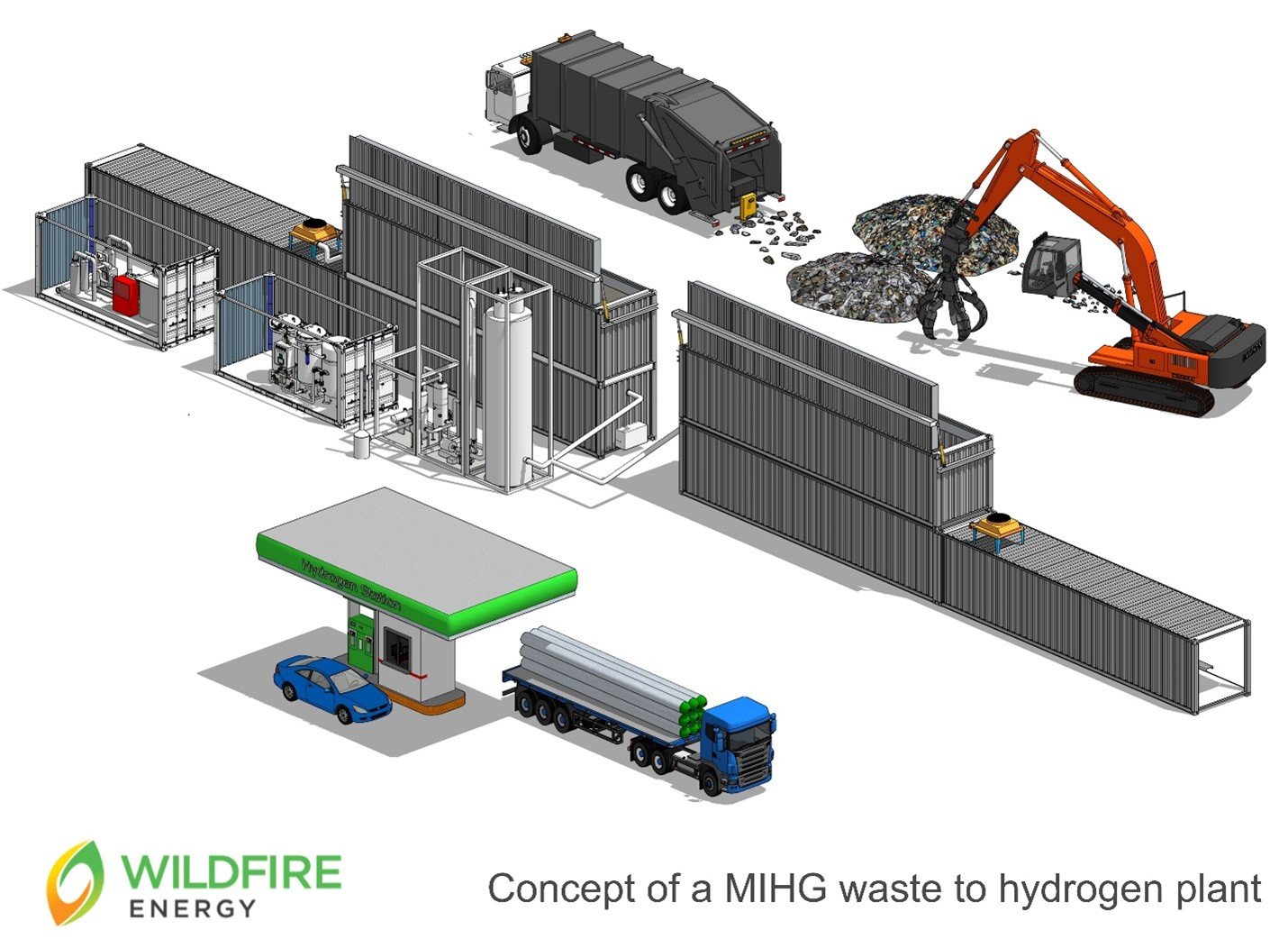

Wildfire Energy's mission is to eliminate landfill by turning residual wastes into renewable electricity and hydrogen at scale using MIHG technology. Using a revolutionary batch process for gasification of residual biomass and wastes, large volumes of feedstock are loaded into an engineered reactor and converted via gasification. This reduces waste to landfill, reduces on-site waste disposal costs and provides dispatchable renewable energy.

The world generates more than 2 billion tonnes of waste each year. This is forecast to grow to more than 3 billion tonnes by 2050, generating over 5% of global emissions. Most of this waste ends up in landfill, or worse, in open dumps. It breaks down releasing methane directly into the atmosphere and also causes soil and water pollution.

While re-use and recycling of waste is prioritised, these solutions still generate smaller streams of residual wastes destined for landfill. There are also large quantities of residual biomass from farming not being utilised. Finally, there is also a need for dispatchable renewable electricity to complement intermittent renewables such as solar and wind, and an emerging demand for low-cost renewable hydrogen to displace fossil fuels.

Wildfire Energy's Moving Injection Horizontal Gasification (MIHG) technology is developed specifically to address these issues and fill a gap in the market for a reliable, low-cost, waste-to-energy solution for deployment at distributed scale.

There are a wide range of use cases, including:

reduce waste to landfill for local councils, waste management operators.

reduce waste disposal costs for mine sites, recycling companies, industrial factory owners, water treatment plants.

produce dispatchable renewable energy for remote communities and independent project developers.

utilise farm wastes to power farms and agricultural co-operatives.

produce renewable hydrogen for heavy vehicle fleets.

The MIHG technology is designed to convert residual wastes into renewable energy products at distributed scale. It applies circular economy principles to connect waste management with energy production and eliminate landfill.

It uses a revolutionary batch process for gasification of residual biomass and wastes. This involves loading a large volume of feedstock into an engineered reactor and injecting an oxidant to convert the waste via gasification into syngas. Unlike other gasification technologies, the oxidant injection point is moved during the gasification process to sweep the active zone through the bed of feedstock. The advantages of this patented approach, which have been proven at Wildfire Energy’s pilot plant, include:

an ability to process wastes without pre-treatment

incorporation of an integrated pre-drying system

production of solidified slag

simple, reliable operation

economic viability for small-scale processing up to 50,000 tpa of waste per site

The MIHG technology is well suited to onsite installation at mine sites, remote villages and regional towns, as well as at industrial factories, recycling centres, water treatment plants and farms.

Wildfire will license the MIHG technology, via a network of partners around the world, to each customer project. Customers may select to buy standard modularised equipment or may design bespoke plants. Wildfire Energy will provide a technology license, technical support, basic engineering package, proprietary equipment, commissioning support and operations and maintenance support throughout the life of the project.

Wildfire Energy's mission is to eliminate landfill by turning residual wastes into renewable electricity and hydrogen at distributed scale using our proprietary MIHG technology.